Mill Production

The facility covers 85,650 square feet. Its 34 grain silos hold 16 million pounds of wheat (270,000 bushels) and can process 200,000 pounds of grain in a single day, including hard red wheat, soft white wheat and durum wheat. The durum wheat, grown on Church-owned farms in Idaho and Montana, is ground into semolina, the raw product for the pasta. The pasta plant contributes to the 20 million pounds of foodstuffs produced at the mill each year.

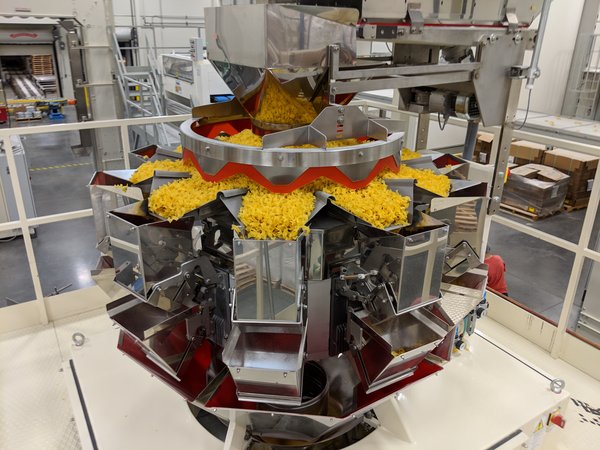

The mill and pasta plant produce white flour, cake mix, potato pearls, granola, hot cereal, rolled oats, rice and pinto beans. On the pasta side, the large pasta-making machine was purchased from Fava, an Italian company, to produce spaghetti, macaroni and cheese and ribbon pasta. In an hour, it can extrude, dry and package 1,700 pounds of spaghetti and 1,300 pounds of macaroni or ribbon pasta. A third line packages macaroni and cheese at a rate of up to 60 boxes per minute.

The mix plant is an automated system that mixes pancake mix and chocolate and yellow cake mix in 1,500-pound batches.